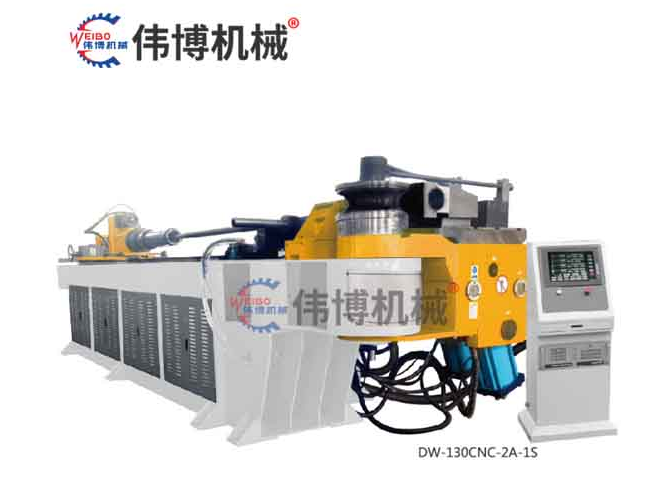

Single-head pipe bending machines are very common in life and have the advantages of multiple functions, reasonable structure and simple operation. But they are machines after all, and because they are designed to bend metal, there are certain dangers that can be dangerous if not handled properly. The drive spindle of the single-head pipe bender is directly inserted from the upper part of the machine head when assembling, which is accurate in installation and convenient in maintenance. The pipe bending spindle and the transmission sprocket are integrally forged, integrally machined, integrally hobbed, connected without keys, and are evenly stressed by double oil cylinders. In the process of driving and bending, the hydraulic system automatically throttles and buffers the arm before it is close to the angle set by the bending, which greatly improves the bending accuracy and returns quickly. During the return process, there is a throttle buffer near the starting point, which greatly improves the The reset accuracy and work efficiency are improved. Fully hydraulic drive.

In the field of pipe processing machinery industry, the main sales force of single-head pipe bender products still relies on the hydraulic system as the core power unit of the machine, and has been constantly improving and improving the pipe bending, cutting, pipe end forming and other processing technologies of pipe bending machine equipment. In the past ten years, due to the continuous improvement and upgrading of the technological revolution, the automatic pipe bending machine and the numerical control operating system man-machine interchange and other technical fields have been gradually updated and upgraded, and the single-head pipe bending machine has become more and more advanced and convenient.

Using our pipe bender on the exhaust pipe of passenger cars, because the hydraulic pipe bender in the past was still unable to achieve the machining accuracy, automatic feeding and automatic corner positioning, these were all done manually and manually. Therefore, to a large extent, it is impossible to achieve the improvement of high precision and efficiency, but in the past ten years, the development of the numerical control technology revolution has bid farewell to the traditional pipe bending machine in the past. The hydraulic pipe bending machine of the past year has made great progress in many technologies.

With the long use of the pipe bender and the hydraulically driven hydraulic pipe bender, some mechanical parts begin to age, so it is necessary to have a certain understanding of our pipe bender equipment before dismantling and analysis to find the cause. For some difficult pipe bending processing, how to improve the processing accuracy of the pipe bending, how to solve the deviation and inaccurate angle of the pipe bending process, the deviation of the general pipe bending angle, you should first check the bending angle of our single-head pipe bender Whether the controller and encoder are damaged, and whether they are loose, after eliminating the encoder problem, we are checking whether there is a deviation of the elbow due to the collision of the elbow arm, and whether the oil temperature is too high, and the elbow speed is uneven and The solenoid valve cannot control the oil pressure very well.

Contact: Manager Ning

Mobile: 15371891344

Email: weibojx@qq.com

Website: www.zjgwbjx.com

Address: Jiangong Avenue, Zhangjiagang City, Suzhou City, Jiangsu Province

【WeChat】