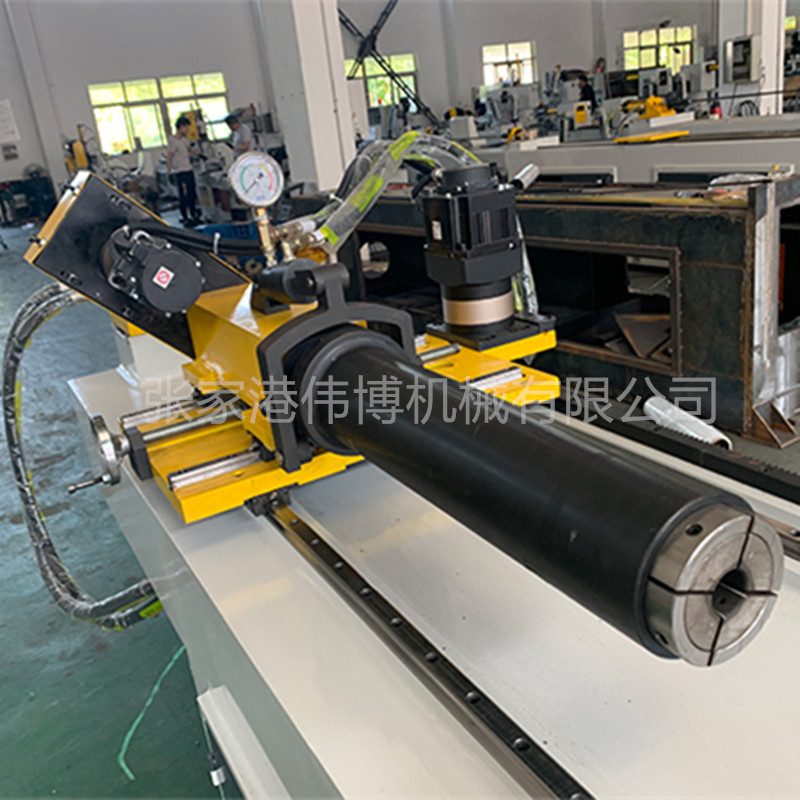

DW-63CNC-2A/1S CNC pipe bending machine

Details

1. Equipment use:

DW-63CNC automatic pipe bending machine This equipment is a CNC hydraulic automatic pipe bending machine. It is equipped with a full-function device for bending three-dimensional space pipe fittings, and the entire pipe bending process is automatically completed by inputting the program. The whole machine has the characteristics of convenient operation, stable performance, high work efficiency and high safety factor, and is an ideal equipment for the pipe fittings processing industry.

2. Equipment features:

2.1. Structural type:

1. The CNC hydraulic pipe bending machine adopts a rotating arm lifting type clamping structure.

2. The hydraulic guide plate side push mechanism is adopted.

3. The bending direction of the pipe fittings is the clockwise rotation of the top view, which is the bending direction.

2.2. Electrical control and operation interface:

1. The operation interface of the CNC hydraulic pipe bending machine adopts a touch screen.

2. Digital display resolution: bending angle 0.01°, rotating tube 0.01°, feeding 0.01mm.

3. The control system of CNC hydraulic pipe bending machine adopts industrial computer control.

4. The elbow parameters can be set (preset) on the operation interface.

2.3. Quality requirements for elbows:

1. The surface of the pipe at the bend is not allowed to wrinkle.

2. There should be no grooves and obvious depressions on the surface of the pipe after bending.

2.4, CNC numerical control hydraulic pipe bending machine equipment has the following characteristics:

1. The operation is simple and easy to learn by using the dialogue-type icon guidance method, and the program input method is concise and systematic.

2. Standard display text: Chinese/English switch. (Other text can be changed as needed)

3. The zuì dà bending program memory capacity is 2 million groups, and each group can be programmed up to 45 bends.

4. Directly input the pipe bending processing parameters, the machine can be single-stepped and paused during automatic operation, so that manual intervention can be performed when bending special pipe fittings, and automatic operation can also be resumed. At the same time, it has a pause function, with automatic and manual functions. After one cycle, the switch is used to start the next cycle, and the emergency stop button is used when an emergency stop is required.