Troubleshooting of Abnormal Noises in CNC Hydraulic Pipe Benders

Maintenance thoughts: When the equipment maintenance is stuck in a bottleneck, when you can’t figure it out, you can completely let yourself go and rest for a while, sit there and think about it, and continue to extend from the faulty part to the next level, extend, and extend…

Fault phenomenon:

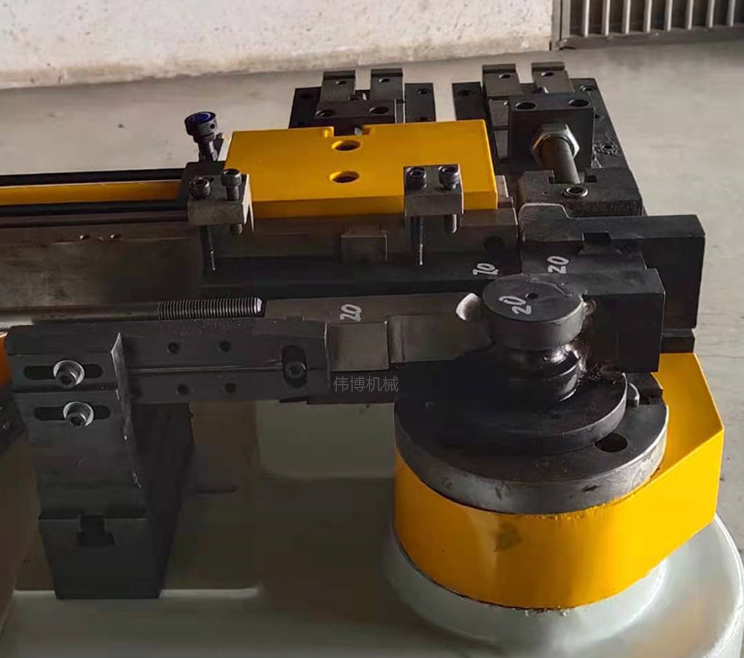

When the pipe bender is working, there is an abnormal sound of da da da da, the sound is very loud, and the size and angle of the processed workpiece change greatly.

Troubleshooting Analysis:

1. The gears and rack meshing parts of the machine head are worn or the rack teeth are broken, causing abnormal noise.

2. The internal bearing of the machine head is worn and damaged, causing abnormal noise.

3. The seal of the cylinder for advancing and retreating bends is damaged, resulting in oil smearing (oil fluids are intertwined when entering or exiting the bend).

4. The pressure of entering and exiting the bend is not coordinated, and the pressure is too large when entering or exiting the bend, causing abnormal noise. Observe the forward and backward bending pressure gauge, and fine-tuning can be performed on the solenoid valve.

5. The internal spring of the solenoid valve spool is damaged, the magnetic force of the coil is insufficient, and the insufficient voltage causes abnormal noise. Disassemble and inspect the solenoid valve, or replace and observe the same type of solenoid valve.

6. The electromagnetic proportional valve is damaged and causes abnormal sound in forward and backward bending. Generally, the electromagnetic proportional valve has a fine-tuning knob on it. It can be fine-tuned, but it must be marked.