What problems do normal CNC hydraulic pipe benders encounter?

What problems do normal CNC hydraulic pipe benders encounter?

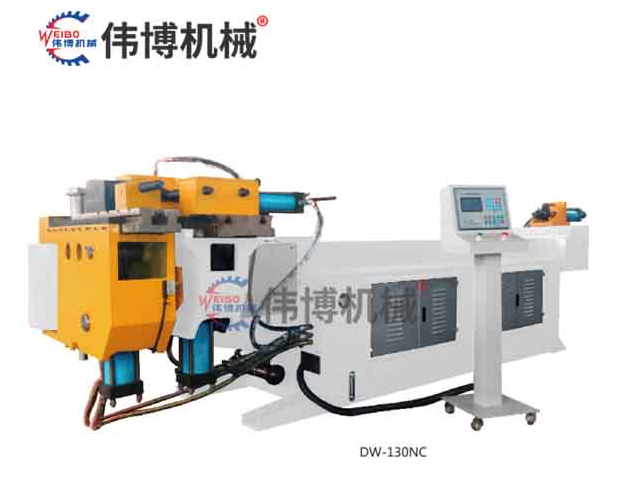

CNC hydraulic pipe bending machines are divided into various models according to customer requirements and can also be customized

Hydraulic pipe bending machine mainly includes distributor and hydraulic part

The problems that occur in normal hydraulic CNC pipe bending are all in the hydraulic part. Z is the key to the hydraulic valve stuck valve. The stuck valve industry is divided into two situations (1) due to the long-term use of the equipment, the hydraulic oil in the equipment is dirty , Some garbage is sucked into the hydraulic valve and blocked, causing the equipment to not work. (2) Double-head hydraulic pipe bending machine equipment rarely occurs when the weather is cool. Normally, it only occurs when the weather is hot. Due to the hot weather, the increase of the working oil temperature of the equipment will also cause the hydraulic valve of the equipment. stuck, causing the device to similarly stop working. (3) There is only one way to solve the above two situations, that is to remove the four screws on the hydraulic valve corresponding to the stop, and then open the hydraulic valve at both ends and clean the middle part. It can be cleaned with diesel oil or blown clean with an air pump.